Consumer Cameras Driving Industrial Innovation: The Rise of Machine Vision

At first glance, consumer cameras and industrial cameras appear fundamentally different in purpose. Industrial or machine vision cameras are typically PC-based systems prioritizing robustness and optimization for image analysis tasks. Their design emphasizes performance metrics like accuracy and reliability under demanding conditions. In contrast, consumer cameras prioritize human-friendly features such as natural color rendering and lighting adjustments tailored to everyday use. These designs don’t need to withstand extreme temperature fluctuations or constant vibration since their primary goal is capturing pleasant memories.

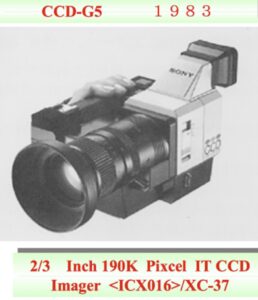

However, the machine vision market owes much of its current capabilities to innovations emerging from consumer camera technology. Charge-Coupled Device (CCD) systems originally developed for professional broadcast and security applications laid important groundwork. The true scaling of this technology happened when it transitioned to commercial products like camcorders—pioneered by devices such as Sony Handycam.

Today’s CMOS sensor advantages stem directly from innovations in cell phone camera technology. Unlike industrial cameras, consumer electronics companies don’t invest heavily in developing proprietary imaging components for mass production applications. The high-volume manufacturing requirements needed to justify these investments typically fall to smartphone manufacturers instead. This creates an interesting challenge: industrial camera producers must transform readily available consumer components into systems meeting machine vision’s exacting standards of reliability and reproducibility.

The relationship works both ways too, as advanced machine vision cameras enable inspecting increasingly complex electronic products like smartphones at scale.

Pixel size represents one key area where compromises exist between these applications. While smartphone manufacturers continuously reduce pixel dimensions to maximize resolution density on small chips, larger pixels generally offer superior performance in industrial settings—though research continues into potential solutions:

- Combining multiple pixels could potentially overcome this limitation…

The evolution of machine vision sensor technology shows strong ties to consumer electronics innovation through several key trends:

- More sophisticated pixel architectures

- Manufacturing using increasingly advanced CMOS processes (< 180 nm)

- Separate technological approaches for analog/digital components versus imaging arrays

- Implementation of back-side illumination and through-silicon via technologies

Consumer electronics represents a powerful catalyst for machine vision advancement in two primary ways: transferring applicable technology developed primarily for consumer applications, alongside using advanced industrial cameras to inspect increasingly complex electronic products manufactured with sophisticated semiconductor fabrication techniques.

Last Updated: 2025-09-04 19:20:32