Electroluminescence Imaging: Enhancing Solar Module Inspection with Advanced NIR Cameras

In today’s renewable energy landscape, photovoltaic (PV) modules require rigorous inspection systems to detect defects and ensure quality. These systems rely on sophisticated cameras capable of capturing detailed images even under low light conditions.

Allied Vision has developed Near-Infrared (NIR) cameras that excel in quantum efficiency and sensitivity for solar module inspections. Their partner DISSEM helped create a cost-efficient imaging solution based on electroluminescence technology—a breakthrough in near-infrared spectrum detection.

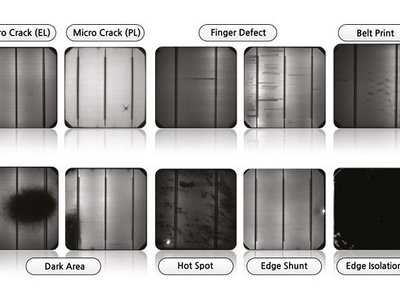

The Challenge of Solar Module Defects

Crystalline silicon devices face significant challenges during manufacturing, including cell breakages from micro-cracks and degraded areas. These structural defects can stem from various sources:

- Challenges in silicon processing

- Crystille crystalline lattice quality issues

- External environmental factors

Traditional visual inspection systems cannot detect many of these hidden flaws. This is where electroluminescence imaging becomes essential—a powerful tool for both crystalline and thin film solar modules.

How Electroluminescence Imaging Works

The technique involves applying direct current to the solar module while measuring photoemission through an infrared-sensitive camera:

- Current flows through the PV module

- The system captures emitted photons in near-infrared spectrum (950-1250nm)

- Software analyzes patterns for defects and performance metrics

This method offers several advantages:

- Detects hidden failures before they become visible

- Measures conversion efficiency based on light emission

- Provides non-destructive quality assessment

Technical Requirements for NIR Cameras

Photovoltaic electroluminescence requires extremely sensitive cameras due to weak emission signals. Key specifications include:

- Wavelength range: 950-1250nm

- High quantum efficiency (QE) at 900nm (

2030%) - Frame readout speed under one second

- Ability to capture complete panels with precise resolution

Electroluminescence System Implementation

A complete inspection system requires specialized software and hardware integration:

- Multiple cameras in a light-controlled enclosure

- Constant current source for consistent measurements

- Advanced image analysis algorithms

Based on defect severity, the system classifies cells as either accepted or rejected.

Manta G-145B NIR Camera Performance

Allied Vision’s Manta G-145B Near-Infrared camera delivers exceptional performance:

- 20~30% QE at 900nm wavelength

- Sony ICX285 CCD sensor with EXview HAD technology

- Anti-blooming feature for high sensitivity applications

Customers appreciate this model’s:

- High sensitivity to weak emissions

- Competitive pricing compared to other CCD cameras

- Intuitive VIMBA SDK software

Operational Benefits

The Manta G-145B offers practical advantages:

- Three operational modes with adjustable frame rates or sensitivity

- Board-level variants available upon request

- Optional optical filters

These features enable manufacturers to implement efficient, cost-effective quality control processes.

DISSEM leverages Allied Vision’s technology to provide affordable solutions without compromising on performance. Their electroluminescence-based imaging system represents a significant advancement in solar module inspection systems—combining cutting-edge hardware and software makes for an integrated solution that enhances defect detection across three key areas:

- Harness-induced EL detection

- Crystalline crystalline structure analysis

- Broken electrode identification before/after lamination processes

The Manta G-145B’s combination of technical excellence, affordability, and user-friendly features makes it an ideal choice for PV module inspection applications.

This advanced camera technology demonstrates how specialized NIR optimization enables manufacturers to enhance their solar module quality assurance systems while maintaining competitive production costs.

Last Updated: 2025-09-04 16:34:18