The Critical Role of Bearing Cage Detection in Modern Machinery

Bearings are fundamental components in modern machinery, yet their performance depends heavily on the integrity of the cage. Suzhou M-vision Electronic Technology Co., Ltd. specializes in developing machine vision solutions to detect defects during bearing production. Their system leverages Allied Vision’s 5MP Manta G-505 cameras to ensure precision and reliability for a global leading supplier of rolling bearings.

Challenges in Bearing Manufacturing

During operation, the cage experiences immense centrifugal forces, shocks, and vibrations—especially under complex high-speed loads. These factors, combined with sliding friction between components, generate significant heat. This can lead to material fatigue or even catastrophic failures like burning or breaking of the cage.

Defect Detection: A Critical Requirement

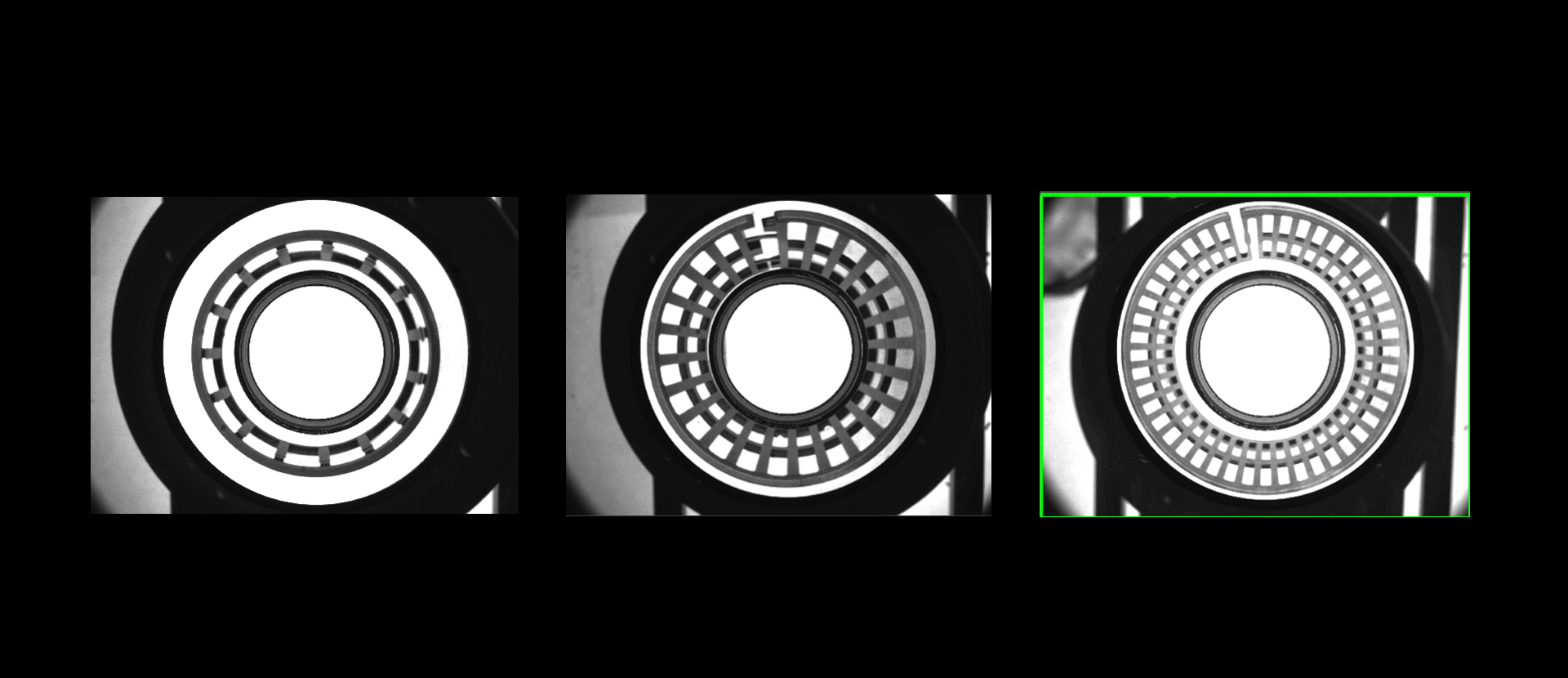

Suboptimal production processes, such as worn molds or unstable grinding equipment, often result in defective cages. These defects include flashes on inner/outer rings, width surfaces, needle slots, and more; scratches or scorches are also common issues. Real-time detection is essential to prevent faulty products from reaching the market.

Real-Time Monitoring with Allied Vision Cameras

Suzhou M-vision’s system employs two Allied Vision 5MP Manta G-505 cameras equipped with a high-performance Sony ICX625 sensor, enabling 15 fps frame rates. This allows rapid imaging at critical production speeds—where the cycle time is as short as 0.4 seconds. The system includes specialized OPTO lenses to capture detailed images of bearing cages.

Defects Commonly Found in Bearing Cages

Two primary types exist: die cast and molding cages, both serving to isolate rolling elements while maintaining structural integrity during operation. Suzhou M-vision’s software detects defects such as flashes or scratches on various surfaces (e.g., outer rings, inner rings, width surfaces) across the production line.

Impact of Defect Detection

The implementation of this system has significantly reduced fault rates by enabling timely equipment maintenance and ensuring consistent product quality. The reliability of Allied Vision cameras provides high-quality imaging for continuous 24/7 operations in demanding environments.

Why Choose Manta Cameras?

- High-resolution imaging to detect even the smallest flaws.

- Real-time performance ensures efficient production processes.

- Full inspection capability supports manufacturing standards.

- Compact design and industrial-grade connectivity simplify integration.

For more details on the Manta camera series, visit Allied Vision’s website.

Last Updated: 2025-09-04 16:42:18