Revolutionizing PCB Defect Inspection: The Role of AI and Advanced Imaging Technology

The competitive landscape of Taiwan’s PCB industry underscores the critical importance of automated optical inspection (AOI) equipment. AOI systems are pivotal in enhancing production capacity and improving defect yield rates by integrating seamlessly into manufacturing processes without halting operations. This technology represents a substantial investment, typically comprising about 15% of total expenditure in PCB manufacturing.

The Challenge of Overkill in Traditional AOI Systems

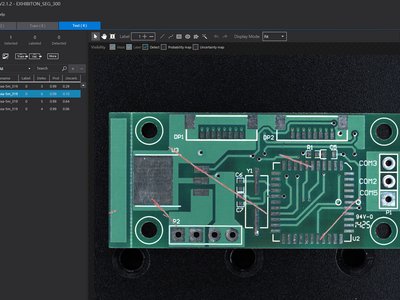

Traditional AOI employs automated visual inspection to scan PCB surfaces and identify defects such as short circuits, copper inconsistencies, open circuits, nicks, burrs, solder slag, missing components, or deflections using advanced image processing algorithms. However, the extremely high yield requirements for PCBs lead to overly sensitive equipment calibration, resulting in a 70% overkill rate—incorrectly flagging defect-free products as faulty. This necessitates secondary manual verification to filter out false positives before products can proceed further down the production line.

G4 Technology’s AI Defect Inspection Solution

Based in Taiwan, G4 Technology specializes in machine vision solutions and AOI systems designed to optimize manufacturing processes while reducing inspection costs. Their innovative approach combines cutting-edge hardware with advanced software:

- Hardware Components:

- Allied Vision Manta G-032C industrial camera (656 × 492 resolution, 80 frames per second)

- Fujifilm high-resolution lens system

- SUALAB’s SuaKIT AI visual inspection software powered by the latest deep learning algorithms

This integrated solution enables real-time capture, detection, marking, and classification of PCB defects through intelligent image analysis.

Enhanced Image Interpretation Capabilities

SUALAB’s deep learning technology leverages artificial neural networks to analyze complex PCB images—significantly improving defect interpretation accuracy compared to traditional visual inspection methods. The system requires approximately 50-100 training images per defect standard, making it highly adaptable to customer-specific requirements while maintaining exceptional performance on production lines.

Performance Characteristics of the Manta G-032C Camera

The Allied Vision camera’s industrial-grade quality and stability make it particularly well-suited for PCB inspection applications:

- Provides reliable 80 frames per second image acquisition

- Supports real-time defect processing in demanding manufacturing environments

- Compatible with various Allied Vision series (including Prosilica GT high-resolution models) based on specific application requirements

Conclusion

G4 Technology’s AI-powered defect inspection system addresses the limitations of traditional AOI by combining sophisticated hardware components with advanced deep learning algorithms. This solution not only improves detection accuracy but also streamlines production processes through automated classification and verification, potentially eliminating unnecessary manual intervention while maintaining high quality standards in PCB manufacturing.

Last Updated: 2025-09-04 16:43:50