Inline Quality Inspection of Textiles Using Texplorer® Software

Textile is everywhere. It serves as one of the most versatile materials across nearly every industry— from fashion and lifestyle to medical applications or automotive uses. Industrial fabrics must meet specific characteristics aligned with strict industrial standards.

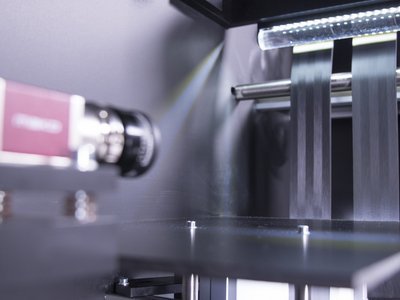

COMVIS, a leading Dutch company in textiles, has developed Texplorer® software—a specialized vision system for inline quality inspection of both textile and industrial fabrics. These inspection units utilize Allied Vision Mako cameras capable of analyzing kilometers of fabric to detect defects that could compromise reliability and quality.

Quality Inspection is Crucial

Every type of textile possesses unique properties based on comfort, strength, absorbency, repellency, abrasion resistance, and breathability. Users depend entirely on the product’s flawless condition— their safety hinges on factors like tensile strength or elasticity in materials such as belts or ropes. A single defect could lead to catastrophic failure.

Therefore, maintaining quality control through inspections is vital during textile manufacturing. Manual checks are not only time-consuming but also prone to human error.

To address this challenge, COMVIS introduced Texplorer® software— a vision system designed for automated inline inspection of textiles and industrial fabrics. It handles two categories: narrow materials (e.g., seat belt webbing, elastic belts, hoses) and wide materials (screens, sieves, medical bandages). These applications demand compact cameras delivering high-resolution images at fast frame rates.

Kilometers of Fabric Inspected in One Go

COMVIS opted for Allied Vision’s Mako cameras to power their inspection units. Integrated with the machine vision software HALCON—which forms part of Texplorer®—two Mako G-234 models capture detailed images without slowing production lines due to their compact design.

These cameras feature Power over Ethernet (PoE), allowing operation via a single cable for both power and data transfer.

The system processes these images in real-time using advanced algorithms, identifying even the most elusive defects. A graphical dashboard visualizes quality metrics from the last 1000 meters with color-coded dots representing different defect types. Captured flaws can be marked physically or logged digitally—including timestamps, positions, batch numbers, and image evidence—to ensure full traceability.

This continuous documentation streamlines production improvement efforts while enabling high-speed inspections—up to 200 meters per minute.

100% Inspection

Automated vision systems like Texplorer® boost efficiency by replacing manual checks. Operators can monitor defects in real-time, edit protocols, and tweak settings without interrupting the line.

Through COMVIS’s technology, manufacturers deliver A-grade products— fully certified according to industrial standards— guaranteeing reliability for safety-critical uses such as automotive components.

Harm Hanekamp from STEMMER-IMAGING noted: “The probability that a car’s seat belt was inspected by COMVIS cameras is nearly 50%,” highlighting the widespread success of this vision solution.

High Performance in a Compact Form

The Mako G-234 combines industrial-grade performance with its small footprint. Equipped with a Sony IMX249 CMOS sensor delivering 2.35 megapixels, it operates at up to 41.2 frames per second when running at full resolution.

This camera captures sharp images thanks to precise alignment and powerful connectivity features— making integration seamless into existing systems:

- Ultra-high-resolution imaging reveals the finest details.

- Consistent real-time performance accelerates production cycles.

- Complete inspection ensures zero defects in final products.

- Ease of installation via compact design, robust standards, and versatile networking options.

Last Updated: 2025-09-04 16:44:50