Fiber Optic Signal Transmission: The Role of Laser Beam Profilers

Telecommunications companies strive to minimize signal loss when feeding sources into fiber optic cables. To achieve this, they rely on sophisticated tools called laser beam profilers. These devices monitor and analyze laser performance data to ensure optimal transmission efficiency.

CINOGY Technologies GmbH, based in Ruderstadt, Germany, specializes in providing high-quality laser beam characterization systems. Their profilers for the near-infrared range—where telecommunication wavelengths fall—are built on modern InGaAs (Indium-Gallium-Arsenide) sensors, complemented by infrared cameras from Allied Vision.

Ensuring Laser Signal Stability

Modern users expect seamless online video streaming and television services without distortion. To meet this demand, telecom providers must maintain stable laser signals, minimizing issues like radiation scattering loss or misalignment during coupling.

Key parameters such as beam position, size, power, and profile require constant monitoring to ensure peak performance. For instance, fiber optic cables have a diameter of roughly 6 µm, making precise alignment critical for maximizing coupling efficiency—the ratio between the original laser beam’s energy and its actual transmission through the cable.

InGaAs Sensors: The Ideal Choice for Near-Infrared Measurements

InGaAs sensors dominate short-wave infrared (SWIR) applications due to their superior wavelength sensitivity. Unlike traditional CCD or CMOS sensors, which are limited to 1,100 nm maximum, InGaAs-based cameras extend the measurable range up to 1,700 nm.

CINOGY integrates either the Allied Vision Goldeye G-008 SWIR (320x256 pixels) or Goldeye G-033 SWIR (640x512 pixels), depending on resolution needs. Both models feature an InGaAs FPA sensor sensitive from 900 nm to 1,700 nm and connect via a Gigabit-Ethernet interface with integrated power.

Real-Time Monitoring for Enhanced Performance

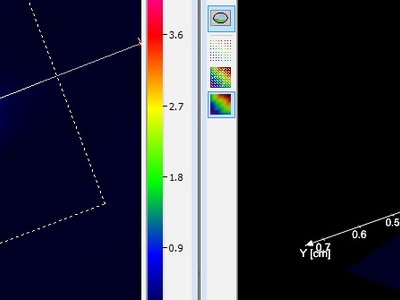

The RayCi analysis software developed by CINOGY enables real-time tracking of beam parameters like coupling efficiency. This allows immediate detection of anomalies such as signal loss or structural irregularities in the laser beam.

By comparing measurements over defined periods, engineers can evaluate performance stability and visualize critical data through two-dimensional profiles that accurately represent beam characteristics.

Key Features of Goldeye SWIR Cameras

- High Sensitivity: Capable of detecting signals across a wide spectral range (900–1,700 nm).

- Low Noise Performance: Cooled sensors maintain optimal sensitivity even during extended exposures.

- Easy Integration: Comprehensive I/O controls and Ethernet connectivity simplify integration into laser profiling systems.

For more details on Goldeye cameras, please refer to the manufacturer documentation.

Last Updated: 2025-09-04 16:52:18