Vision Guided Robotic Systems: Revolutionizing Industrial Automation

Vision systems and robotics are increasingly converging in industrial applications, leading to innovations like Vision Guided Robotic (VGR) systems. These systems allow robots to identify and manipulate objects with extreme precision without relying on fixed environments or predetermined positions.

Recognition and Location of Randomly Stacked Objects

In traditional robotic setups, a robot relies on precise location systems only when operating in fixed work environments. However, VGR systems eliminate this dependency by enabling real-time object localization using advanced vision technology.

VGR combines the power of robotics and vision to perform tasks like picking, which involves identifying an object’s position and then moving it to a designated location. A well-known example is the “pick-and-place” system, where robots identify objects on a conveyor belt and relocate them with precision.

Bin Picking System Based on Stereo Vision

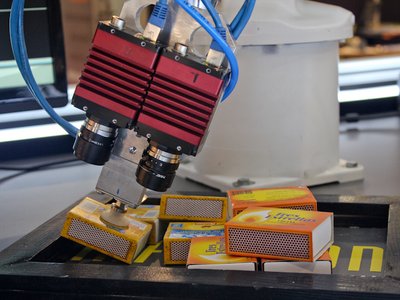

One of the standout advancements in VGR technology comes from Infaimon—a distribution partner for Allied Vision’s cameras. They’ve developed a stereo vision-based bin picking system that allows robots to extract parts stacked randomly in bins.

This system uses two high-resolution GigE Vision cameras mounted directly onto the robot’s arm. These “artificial eyes” capture synchronized images, creating a detailed 3D map of objects within reach. This enables precise localization and extraction even when items are disorganized or stacked irregularly.

For optimal performance, Allied Vision offers two camera models:

- Mako G-125: A compact (29 x 29 mm) GigE Vision camera with Sony’s ICX445 CCD sensor.

- Prosilica GT1290: A high-performance model ideal for advanced applications requiring faster readout and precise synchronization.

Both cameras support “Power over Ethernet” (PoE), simplifying installation by combining power delivery and data transfer into a single cable.

No Time Lost: Efficiency Through Real-Time 3D Mapping

Unlike traditional systems that require objects to be aligned or stacked consistently, VGR robots using stereo vision can operate in dynamic environments. This flexibility eliminates the need for pre-sorting or aligning items.

The dual-camera setup also offers distinct advantages:

- Faster production cycles due to improved robot mobility.

- Easier identification of complex parts even when densely packed.

- Reduced downtime and increased throughput compared to laser-based or time-of-flight systems.

Synchronized Images: Precision in Motion

For stereo vision to work effectively, the cameras must capture synchronized images. The Mako G-125 provides a compact solution with flexible input/output options, while the Prosilica GT1290 supports advanced features like Precision Time Protocol (PTP), ensuring sub-microsecond synchronization across Ethernet networks.

Key Benefits of Stereo Vision-Based VGR Systems

- Increased Flexibility: Objects don’t need to be stacked uniformly.

- Cost Efficiency: Lower hardware costs compared to 3D systems based on laser triangulation or time-of-flight technologies.

- Enhanced Performance: Faster processing and safer identification, even in complex scenarios.

Learn More About Allied Vision’s Cameras

For detailed specifications of the Mako G series or Prosilica GT models, visit our website. These cameras are designed to meet a wide range of industrial needs while maintaining ease of integration and reliability.

Last Updated: 2025-09-04 16:54:14