HDD Production: The Critical Role of Quality Control

As hard disk drive (HDD) manufacturers ramp up production to meet growing storage demands, ensuring product quality has become increasingly vital. Modern HDDs feature more complex designs that require higher precision and faster manufacturing cycles. This article explores how Flexon’s Visual Machine Inspection (VMI) addresses these challenges with advanced camera technology.

The Need for Precision in HDD Manufacturing

The surge in digital storage demand over the past decades has driven massive growth in HDD production. These magnetic storage devices use rapidly rotating disks coated with magnetic material to store and retrieve data. Beyond basic functionality, HDD cases must provide:

- Perfect component security throughout product lifetime

- Effective sealing mechanisms

- Protection against dust, humidity, shocks, and vibrations

Visual Machine Inspection (VMI): An Overview

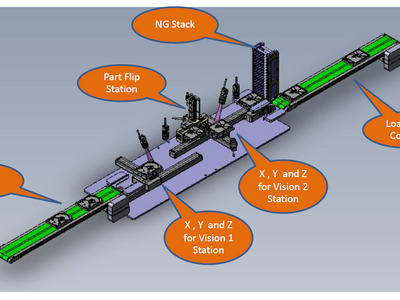

Flexon’s VMI system employs two stations with specialized cameras to inspect HDD cases for critical defects including missing threads, incomplete threading, damaged threads, and incorrect machining. The inspection process consists of three key stages:

Station 1

- Features two Allied Vision cameras: Mako G-125B PoE (for defect detection) and Manta G-505B PoE (for positioning guidance)

- Conducts a top-part inspection within 4.2 seconds, capturing 14 images

- Identifies defects including missing/incomplete threads, damaged threads, missing machining surfaces, and missing drill holes

Station 2

- Equipped with four cameras: three Mako G-125B PoE (for detailed inspections) and one Manta G-505B PoE (for positioning)

- Inspects all sides for threading issues

- Examines the back part for multiple defect types including missing riveting, drill holes, machining surfaces

- Features camera 6 to locate thread hole positions

Both stations complete their respective inspections within 4.8 seconds.

Technical Specifications of Allied Vision Cameras

Mako G-125B PoE

This GigE vision camera utilizes a Sony ICX445 CCD sensor (Type 1/3, 6.0 diagonal) with EXview HAD technology. It delivers:

- Up to 30.3 frames per second at full resolution

- Compact analog-style mounting design

- Power over Ethernet functionality

- Three opto-isolated outputs and a large image buffer

Manta G-505B PoE

This advanced GigE vision camera offers:

- Sony ICX625 CCD sensor (Type 2/3, 11.016 mm diagonal)

- Up to 15 frames per second at full resolution

- Sophisticated color correction features

- Metal housing for durability

- Multiple modular options

The Benefits of VMI

By implementing Flexon’s Visual Machine Inspection system, HDD case manufacturers can achieve:

- Increased productivity through automated quality checks

- Higher precision in defect detection

- Reduced production lead times

- Consistent product quality at scale

This advanced inspection solution helps manufacturers meet the escalating demand for HDDs while maintaining strict quality standards.

Note: This article has been condensed to highlight key technical points while removing redundant content from the original source text.

Last Updated: 2025-09-04 17:01:08