Highly Automated Production Unit for Alvium Officially Inaugurated

Allied Vision has installed a new highly automated production line at its headquarters in Stadtroda, Germany. This cutting-edge facility is dedicated to the series production of their revolutionary Alvium camera series. The inauguration ceremony on June 21st was attended by local politicians, media representatives, suppliers, and business partners.

Innovative Production for an Innovative Product

The Alvium camera series represents a groundbreaking innovation in image processing technology. Allied Vision has developed proprietary ALVIUM® technology, which is built around an Application-Specific Integrated Circuit (ASIC). This ASIC includes an integrated image signal processor (ISP) and a comprehensive image processing library (IPL).

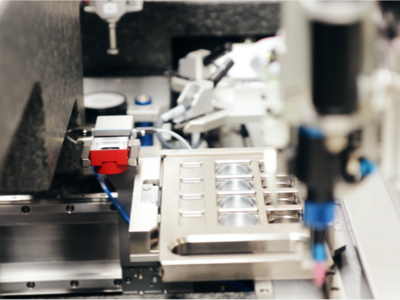

To support this innovative product, the company invested significant resources to build a specialized automated high-tech production line. The system was specifically designed for the Alvium manufacturing process and manufactured in Germany.

The production facility features advanced automation with clean rooms meeting ISO class 6 and 8 standards, ensuring exceptional quality control. Individual components—including electronics, optical filters, and housings—are assembled using patented processes that guarantee precision before assembly.

This versatile production line can handle various lens mounts (C-Mount, CS-Mount, S/M12-Mount) and housing options (bare board, open, or closed). All operations comply with strict quality management standards, including ISO 9001 and ISO 13485 for medical technology, as certified by TÜV.

The entire process is monitored through an integrated image processing system equipped with Allied Vision cameras.

High Quality at a Reasonable Price

Industrial cameras require precise automated sensor alignment to deliver sharp, distortion-free images. The Alvium production line utilizes innovative mounting technology that ensures perfect sensor alignment from the start. This eliminates the need for additional calibration and enhances camera reliability.

Each finished camera undergoes optical precision testing during final quality checks. These measurements are fed back into the production system to enable continuous improvement through short cycle times, which helps maintain competitive pricing while ensuring high output volume.

“Gerd Völpel, Chief Operations Officer of Allied Vision, expressed satisfaction with the new production line’s implementation. ‘This fully automated system establishes new benchmarks for quality and efficiency in industrial image processing,’ he noted. ‘Customers benefit from innovative camera modules offering an unbeatable price/performance ratio combined with outstanding German engineering excellence.’”

Downloads

- PR Allied Vision Inauguration Alvium Productionline (32 KB)

- Inauguration-Alvium-Production.jpg (1 MB)

- Alvium-Open-Housing_Beauty_02_72dpi.jpg (926 KB)

Last Updated: 2025-09-04 17:11:59