Understanding Infrared Radiation and Sensor Performance in SWIR Cameras

What is the Infrared Spectrum?

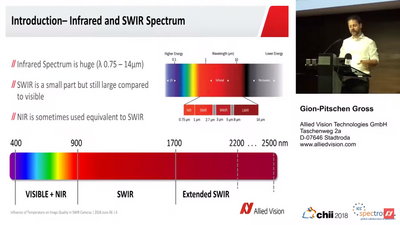

Infrared radiation occupies a position within the electromagnetic spectrum, located between visible light and microwaves. This spectral range spans from 750 nm to over 14,000 nm wavelength. For practical purposes, it is often divided into four subcategories: Near-Infrared (NIR), Short-Wave Infrared (SWIR), Mid-Wave Infrared (MWIR), and Long-Wave Infrared (LWIR).

While the SWIR region of the spectrum is invisible to the human eye, its interaction with objects closely resembles that of visible light wavelengths. This makes it particularly useful for non-visible imaging applications.

How SWIR Camera Sensors Work

Most modern SWIR camera sensors are constructed using Indium Gallium Arsenide (InGaAs) material. These quantum detectors function similarly to silicon-based CCD or CMOS sensors by converting photons into electrons. The key components of these sensors include:

- InGaAs photodiodes that detect infrared light

- Silicon-based read-out integrated circuits (ROIC) for signal processing

A notable characteristic of InGaAs photodiodes is their smaller band gap energy compared to silicon pixels, which influences sensor performance at operational temperatures.

The Impact of Dark Current on Image Quality

Dark current refers to electrical current generated in the absence of light, producing a visible signal in images. This phenomenon occurs due to thermal excitation of electrons within the InGaAs material. Key observations about dark current:

- It varies significantly between different sensor models

- Its magnitude increases substantially with rising temperature (approximately doubling every 9°C increase)

This effect is demonstrated when comparing identical scenes captured at different temperatures, resulting in distinct histogram differences due to variations in black level and noise characteristics.

Temperature Effects on Spectral Sensitivity

Sensor operating temperature significantly influences spectral sensitivity:

- A 40°C reduction (from 25°C to -15°C) shifts sensitivity by approximately 25 nm toward shorter wavelengths

- This wavelength shift is particularly critical for applications requiring operation at spectral extremes

When working beyond 1,700 nm, temperature control becomes essential. While higher temperatures increase noise through greater dark current production, they often produce better signal quality in the upper end of the spectrum.

The Importance of Temperature Control

Precise temperature management is crucial for optimal SWIR camera performance because:

- It directly affects both spectral sensitivity and dark current levels

- Maintaining consistent image quality requires balancing these factors

All Goldeye SWIR cameras incorporate sophisticated temperature monitoring systems with three strategically placed sensors:

- Inside the InGaAs sensor housing

- On the sensor board

- On the mainboard

Advanced Cooling Solutions

To counter thermal gradients and maintain stable operating temperatures, most models feature specialized cooling technologies:

- TEC1: Single-stage thermo-electric cooling (example: Goldeye G/CL-033 TEC1)

- TEC2: Dual-stage thermo-electric cooling (example: Goldeye G/CL-032 Cool TEC2)

- Additional cooling fans

The specialized Cool models further enhance thermal management through nitrogen-filled cooling chambers that protect sensors from condensation in high-humidity environments.

Learn More About Our SWIR Camera Technology

For detailed technical specifications and performance characteristics, please explore our complete line of Goldeye SWIR cameras on the product pages or contact our imaging experts for personalized guidance.

▶️ Video Resource: Discover how temperature variations impact image quality in NIR/SWIR camera systems.

Last Updated: 2025-09-04 17:18:35