Balancing Performance and Cost in Embedded Vision Systems: Pre-Processing, Advanced Processing, and Post-Processing Considerations

Embedded systems are generally highly sensitive to costs, making it crucial to evaluate overall system expenses when making decisions. Increasingly, embedded systems incorporate image-processing capabilities, and with embedded processors becoming more powerful, these functions grow increasingly complex. However, cost sensitivity remains a key factor in design choices.

Image correction and processing require significant computational resources, so designers must consider the total cost impact on their systems. There are two primary types of image processing tasks in vision systems: pre-processing and advanced processing. Both demand substantial processing power to achieve desired results.

Image Pre-processing, Advanced Processing, and Post-Processing

Image pre-processing involves converting raw sensor data into a usable image format by applying corrections such as defect pixel fixes, white balance adjustments, gain controls, and noise reduction. These steps optimize the image for subsequent software analysis. Once optimized, advanced processing techniques enhance specific aspects like sharpness or color accuracy using look-up tables.

In embedded systems, these pre-processing tasks are typically handled by an Image Signal Processor (ISP). The goal is to prepare the image for post-processing—the core application-specific analysis conducted on a system’s main processor. For instance, adjusting contrast can improve edge detection capabilities.

Post-processing applications vary widely depending on system goals, such as facial recognition or license plate identification in surveillance systems, or quality assessment in industrial inspections. These complex algorithms rely heavily on processing power from the host embedded board.

Camera Module vs. Sensor Module

Both image corrections and advanced processing consume significant resources. Historically, designers relied on low-cost sensor modules for basic image capture without advanced features like ISP integration. However, camera manufacturers from the machine vision industry have introduced advanced camera modules with built-in ISPs that handle complex tasks like defect correction, color calibration, and cropping.

Products like Allied Vision’s ALVIUM® technology combine high-performance hardware with extensive optimization capabilities at an affordable price point. These integrated solutions deliver ready-to-use images to the host system without requiring separate processing components.

Why Low-Cost Sensor Modules Can Increase Costs

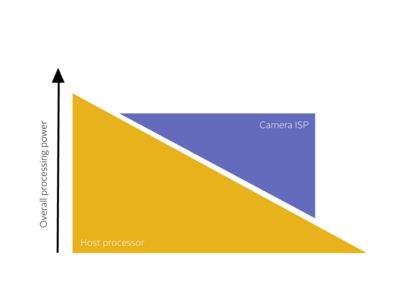

Although sensor modules may appear cheaper initially, they often require more powerful host processors for image correction tasks, which can drive up overall system costs significantly despite lower upfront hardware expenses. Advanced camera modules with built-in ISPs allow designers to use less capable—and therefore less expensive—host components.

The True Cost of Image Processing

Conventional wisdom suggests that low-cost sensor modules are ideal for budget-conscious designs; however, this approach may overlook hidden costs associated with processing requirements. Investing a few dollars more in an advanced camera module can sometimes yield substantial savings on host-side expenses by reducing the need for powerful processors and complex algorithms.

The emergence of ISP-integrated camera modules represents a fundamental shift in embedded vision design philosophy: system-level optimization must consider all components, not just individual parts or initial purchase prices. Balancing processing requirements between camera hardware and host systems remains essential for achieving truly cost-effective designs.

Last Updated: 2025-09-04 17:31:40