EB200E Smart Encoder: Revolutionizing Machine Design with Efficiency and Flexibility

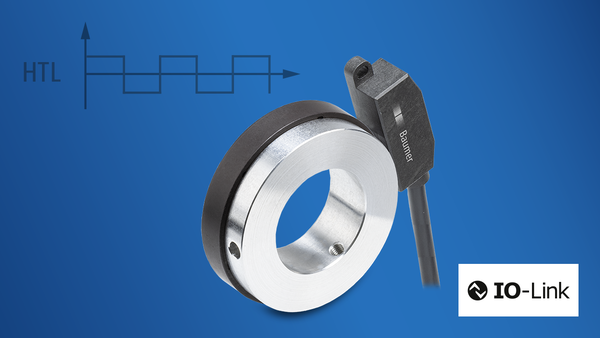

The introduction of smart encoders has significantly simplified both electrical and mechanical integration, making it more cost-effective than ever before. Baumer’s new bearingless encoder, the EB200E, exemplifies this innovation by offering compact design without requiring complex modifications to existing machinery setups. This device stands out as the first smart incremental bearingless encoder equipped with IO-Link technology on the market today—a feature that streamlines cabling costs and effort considerably while eliminating the need for extra hardware components through its integrated speed monitoring functionality.

The IO-Link interface facilitates connecting up to eight encoders using standard cables, thereby reducing implementation expenses significantly. This capability paves the way for entirely new applications where parameterization can be managed via this user-friendly interface—configuring two switching outputs serves directly as a mechanism to monitor operational states such as overspeed conditions or direction changes without additional hardware support. Additionally, EB200E maintains compatibility with conventional HTL signal outputs ensuring seamless integration into legacy systems if required by specific application needs.

Designed for space-efficient machine construction given its shallow installation depth of just 12 mm combined with adaptable shaft diameters specifications tailored to various axis requirements—this encoder utilizes non-contact sensing between the sensor head and magnet ring thus proving resilient against environmental factors like dirt accumulation or mechanical vibrations from shocks or movement during operation. To further ease deployment across industrial settings, Baumer has developed its Sensor Suite—a convenient PC-based tool designed specifically for straightforward parameterization tasks alongside data visualization capabilities enhancing overall system usability considerably.

Last Updated: 2025-09-04 22:49:16