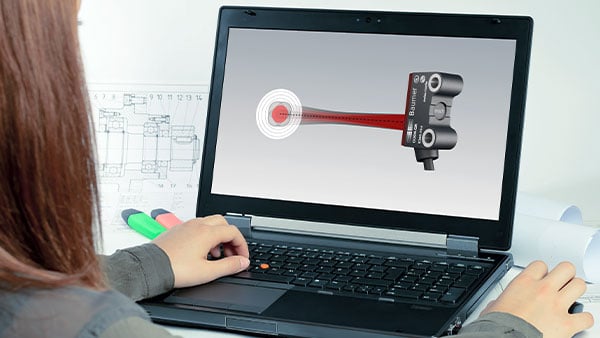

Baumer Combines Safety with Comfort in Design-In Thanks to 3D CAD Data with Integrated Beam Path

Thanks to their high precision and reliability, the optical O200 miniature sensors ensure maximum process safety in factory automation. However, they offer even more benefits: They significantly reduce designers’ effort during design-in.

With the O200 miniature sensors, Baumer is the only supplier that provides its customers with 3D CAD data featuring an integrated beam path—a solution to a longstanding problem. Previously, when integrating a sensor into machinery or systems, designers needed to painstakingly reconstruct the sensor beam path from data sheets in order to determine exact alignment and mounting specifications for collision avoidance and interference prevention.

This manual reconstruction was particularly challenging for users who frequently integrate numerous sensors with varying sizes and functional principles. By incorporating the beam path directly into CAD data, Baumer addresses this issue effectively.

Furthermore, aligning the light beam precisely with mounting holes enables straightforward installation without complex adjustments—a feature that streamlines implementation considerably.

Reliability and Convenience for Design-In and Planning

More than just standard offerings—this is the principle guiding Swiss sensor manufacturer Baumer. For Markus Imbach, Senior Product Manager at Baumer, this isn’t merely a marketing phrase: “With O200 sensors, we deliver substantial added value throughout customers’ journey—from design through commissioning to ongoing operation.”

These devices with LED and laser light sources achieve exceptional detection reliability even under intense ambient lighting or reflective conditions—so much so that additional mechanical protective measures become unnecessary.

Moreover, they are the first sensors whose 3D CAD data incorporate beam path details. This integration empowers designers: They can immediately utilize information on beam geometry, range characteristics for different functional principles (including diffuse sensors with background suppression, SmartReflect®, retro-reflective or through-beam models), and variations across light sources (red-light LED, Baumer PinPoint LED, or laser) without deriving specifications from manufacturer documentation.

Furthermore, data reveals a minimal variation—only 2% for O200 units—but even slight deviations warrant attention. Designers can account for potential production lot differences by reviewing supplementary beam path projections.

This approach showcases how safety and convenience merge seamlessly within these sensors.

Additionally, referencing the beam geometry to mounting holes (qTarget®) eliminates tedious calibration tasks entirely; accuracy remains consistent across all models in the O200 family. Consequently, avoiding collisions or reflecting interference becomes possible from design inception onward.

Maximum Flexibility for Every Application

The comprehensive portfolio of O200 miniature sensors caters perfectly to diverse detection requirements with and without reflectors. These versatile detectors even handle ultra-black, shiny surfaces; transparent materials; small objects; and narrow gaps effectively.

Their high functional reserves combined with extreme ambient light immunity substantially minimize false-trigger risks that could lead to machine downtime—ensuring maximum operational safety in process environments.

The standardized design along with uniform mounting hole spacing (accommodating stainless steel sleeves or M3 threaded inserts) offers exceptional flexibility regarding installation positions while maintaining compatibility across various applications.

Compact form factors paired with diverse configurations further enhance machinery design freedom. The inclusion of integrated beam path details within CAD data lessens initial engineering effort—while obviating the need for complex ambient light mitigation strategies through hardware modifications.

In summary: O200 miniature sensors set new benchmarks in reliability, precision, and adaptability.

Last Updated: 2025-09-04 22:56:18