Four Ninety: Revolutionizing Inspection for Rotationally Symmetrical Products

In traditional approaches to inspecting rotationally symmetrical products, such as cylinders or wheels, operators typically rotate these objects fully around their axis at a fixed speed while capturing the images with a single camera. This method relies on acquiring one complete image per product through standard imaging techniques followed by detailed analysis via specialized software. However, this process often introduces challenges when inspecting seam regions where adjacent sections of an object meet—these areas frequently appear distorted or unclear in captured images.

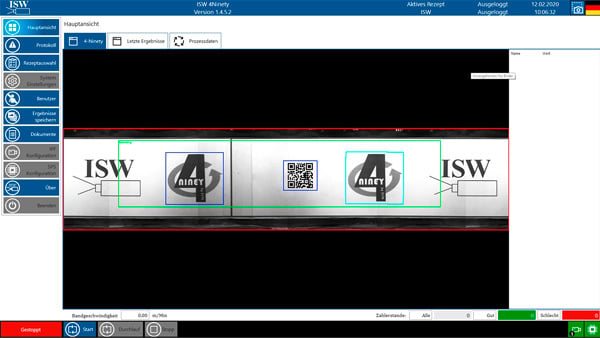

At ISW GmbH, Stefan Tukac highlights the limitations: “The drawbacks of previous testing systems include difficulties in identifying inconsistent surface features at product seams, which restricts error detection to serial defects.” To overcome these issues, ISW developed a novel 100% control system capable of detecting any single defect during production without disrupting throughput. Dubbed “4ninety” after six months of intensive development, this solution employs four Baumer cameras positioned strategically around the product.

Each camera captures a distinct 90-degree segment with precise overlap management enabled by advanced software algorithms. Together, these sensors provide complete spherical coverage through seamless integration: “The system’s name reflects its core functionality—four cameras each responsible for monitoring one-quarter of the object’s circumference.”

The proprietary image-processing engine combines four individual images into one continuous panoramic view without distortion or overlapping artifacts. This allows inspectors to identify surface anomalies across all angles simultaneously, providing a comprehensive quality assurance solution that meets modern manufacturing requirements.

Last Updated: 2025-09-04 23:00:57