Smart At-Line Quality Control of Rubber Seals with PosCon HM

Measuring object height is a critical aspect of quality control processes. To address this need, Baumer has introduced the PosCon HM light-section sensor—a compact and unique measuring device designed specifically for such tasks. This smart, pre-configured profile sensor offers five different measurement modes tailored to various applications. Importantly, it does not require precise positioning of the objects being measured.

The PosCon HM is capable of delivering reliable measurements even on challenging surfaces like shiny or extremely dark materials. Combined with its high accuracy—up to 2 μm—it can be used in a wide range of at-line, off-line, and inline quality control scenarios.

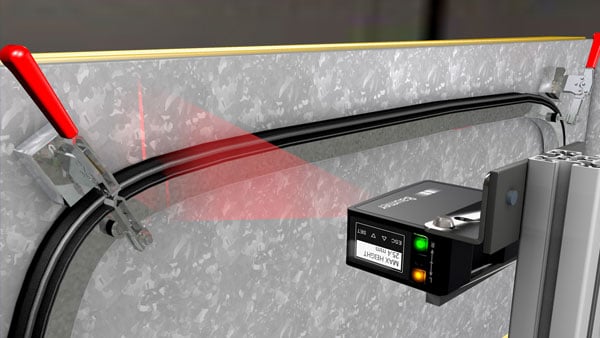

One practical example is the inspection of black rubber seals for side windows in the automobile industry. In this application, random samples are tested off-line on specialized equipment. The seals are placed into custom mounts to ensure stability during measurement. While their shapes and curves may differ, they must not exceed specific dimensional limits. Here, the PosCon HM handles both curve analysis and material challenges effectively.

Equipped with advanced algorithms, this sensor can process up to 600 height data points per measurement cycle. It calculates the maximum height regardless of object placement—a capability only offered by the PosCon HM. The device also supports measurements at a rapid rate—up to 1540 Hz—ensuring precise and timely results for real-time quality checks.

Another key use case involves inspecting metallic, preformed components like car doors. By deploying multiple sensors in close proximity, users can verify the correct form of these parts through comprehensive point-by-point analysis. The PosCon HM directly provides measurements in millimeters, allowing instant OK/Not OK assessments at each test location.

Last Updated: 2025-09-04 23:34:28