Understanding AlphaProx Factor 1: A Revolutionary Approach to Distance Measurement with Metals

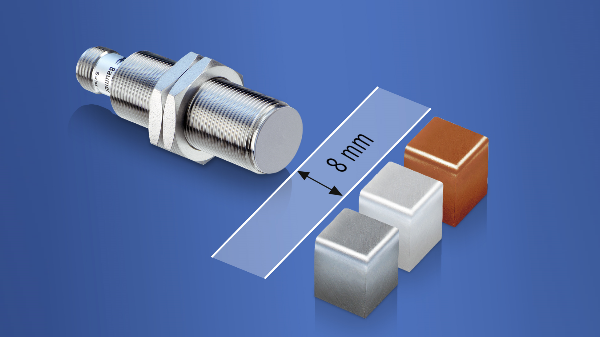

The AlphaProx IR18.D08F sensor from Baumer represents a significant advancement in inductive distance measurement technology. This innovative device maintains an impressive constant measuring range of 8mm regardless of the target object’s metal composition—a feature that sets it apart from traditional sensors.

Unlike conventional systems, which often struggle with aluminum and non-ferrous metals (typically experiencing up to 50% reduced measuring ranges), this sensor delivers consistent performance across all materials. This breakthrough eliminates the need for multiple specialized sensors in multi-metal applications or complex adjustment processes previously required when different metal targets were used.

The device’s design incorporates several technical advantages:

- Robust M18 housing

- Linearized measurement output

- Minimal temperature drift (typically <0.1% FSO/50°C)

- Simple installation process

The innovative “teach-in” concept allows for quick configuration regardless of the connection method—whether through cable, teach-in adapter, or controller interface. This streamlined setup procedure effectively eliminates laborious mechanical adjustments that were standard in earlier systems.

This technology finds particular application in diverse industrial sectors including material handling, mechanical engineering, and lightweight construction due to its combination of precision, reliability, and ease of integration.

As part of Baumer’s AlphaProx platform—a flexible solution with integrated evaluation electronics—these sensors provide an excellent price-performance ratio for automation applications. Their adaptability makes them suitable for various measurement challenges from confined spaces to high-precision requirements.

The consistent performance characteristics across different metals make this sensor particularly valuable in environments where multiple materials must be measured simultaneously or sequentially without recalibration.

Last Updated: 2025-09-04 23:38:02