High Sensitivity Measurement with Baumer's AlphaProx Sensors

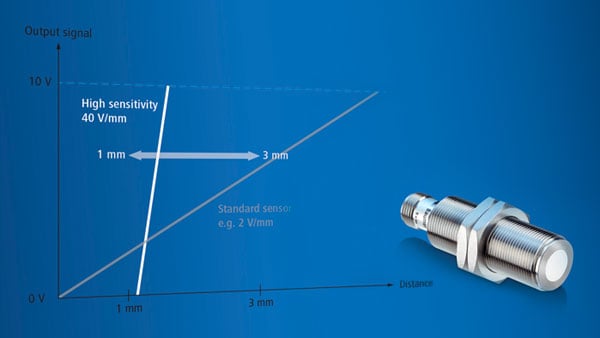

Baumer has introduced a groundbreaking innovation with its AlphaProx IR12 and IR18 High Sensitivity sensors—these are the first teachable standard inductive sensors designed for measuring minute positional changes globally. These sensors stand out due to their high sensitivity and linearity, making them ideal for indirect force measurement applications. For instance, in machinery, the deformation of a metal support can be used to infer the load acting on it—a task previously requiring costly eddy-current sensors or difficult-to-install strain gauges.

The AlphaProx High Sensitivity sensors boast a measuring range of 0.25 mm and excel at detecting micrometer-level changes in challenging environments. Their compact design, devoid of external amplifiers, also offers an excellent price-performance ratio, along with the ease of installation facilitated by the innovative teach-in method.

This sensor operates through a straightforward one-step “teach” process: position it approximately 1 to 3 mm from the target object and issue a teach command. The device then learns its current output value (offset correction), enabling precise measurements without laborious mechanical adjustments. This flexibility allows users to set start/end positions or even middle points, making these sensors exceptionally well-suited for vibration analysis in shafts.

Moreover, AlphaProx serves as an ideal contactless alternative to traditional strain gauges—eliminating installation hassles while maintaining accuracy. With customizable measuring ranges available upon request and no impact on the measured object during operation, they seamlessly adapt to various industrial automation needs from confined spaces to harsh environments.

Last Updated: 2025-09-04 23:38:34