The Greyparrot Analyzer uses The Imaging Source DFK 39GX265-Z20 industrial cameras for AI-powered waste sorting optimization with computer vision technology.

By 2030, the global population is expected to generate over 2.59 billion tons of municipal solid waste annually. Astonishingly, up to 95% of this material can be recovered or recycled, yet World Bank data shows that only about 19% actually gets recycled or composted worldwide.

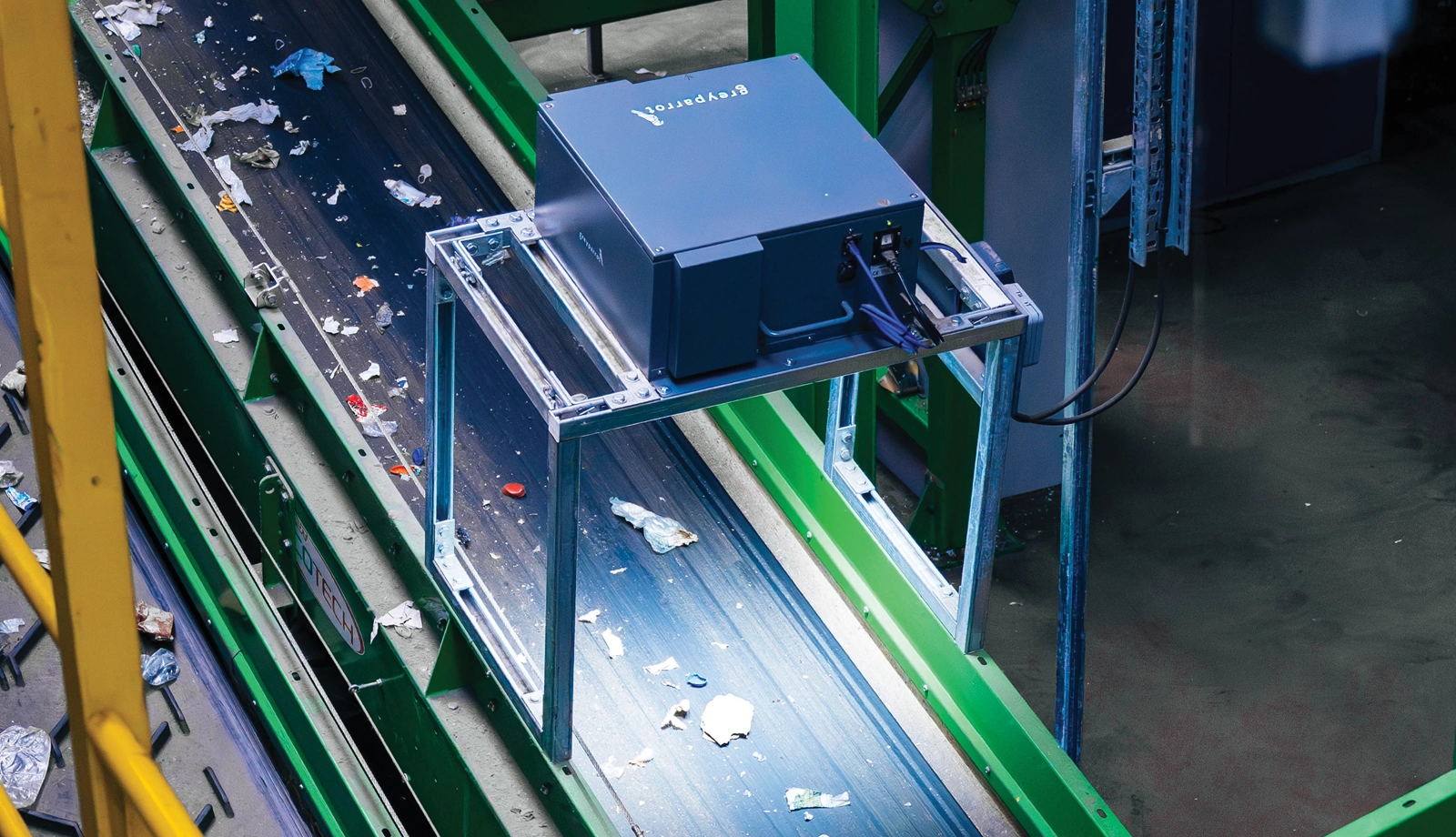

London-based AI developer Greyparrot is tackling this challenge through computer vision technology aimed at boosting recycling efficiency and reducing environmental impact. Their flagship product, the Greyparrot Analyzer, incorporates The Imaging Source’s robust DFK 39GX265-Z20 industrial camera with a powerful 20X optical zoom.

This system captures live images of waste passing through sorting facilities, enabling real-time analysis by Greyparrot’s AI. Facility managers receive actionable insights to improve sorting performance and generate detailed reports on their materials.

Industrial Zoom Cameras: Imaging Flexibility and Easy Integration

The Analyzer is designed for seamless integration into existing recovery facility infrastructure. Its flexibility in controlling camera focus and field of view (FoV) is essential given the variable equipment dimensions, such as conveyor belt width. VP Alisa Pritchard explains that robustness, remote zoom and focus control, GenICam standard support, and external trigger capabilities were critical requirements.

The DFK 39GX265-Z20 meets these needs by allowing rapid adjustments for changing working distances, fields of view, and lighting conditions. The camera’s software-controlled zoom and autofocus are particularly useful for adapting to varying customer facility requirements.

Customized Imaging Solution

Recovery facilities often operate under harsh conditions with temperature variations, humidity, vibration, dust, and particulate matter being common factors. Continuous detailed waste data depends heavily on hardware uptime. To address this, The Imaging Source enhanced the camera design by adding metal brackets to its lens system for better protection.

Imaging Pipeline

The industrial zoom camera produces a live image stream at approximately 32 frames per second. While not every frame requires analysis (typically about one out of ten images is analyzed in detail), each image undergoes basic preprocessing like intensity normalization before being examined by the system’s trained convolutional neural network (CNN).

The Analyzer processes these images locally in real-time, uploading the resulting data to a cloud-based portal for customer access. The AI waste analytics system gathers seven layers of detailed information about each waste item: material composition, mass, financial value, size, food-grade status, potential CO2 emissions, brand, and SKU.

Large-Scale Visual Recognition Improves Composition Tracking

Computer vision technology has dramatically accelerated automated waste processing in the past two decades. Previously, facilities relied on inefficient manual spot sampling, which only captured about 1% of processed material data according to Pritchard.

By leveraging image data and deep learning, the Analyzer automates this process, enabling analysis of valuable insights from what was previously untapped information locked within the remaining 99% of waste. This system provides comprehensive insights on composition that were previously unavailable. The system is not only far more efficient but also significantly cheaper than traditional methods - identifying PET bales manually requires about 30 hours and costs around €2,000 versus just six hours for approximately 20€ using the Analyzer.

AI-powered sampling can be up to 250 times cheaper than traditional manual methods. Pritchard notes that large-scale visual recognition solves a decades-long data gap by capturing visual information needed to track waste stream composition - sensors like near-infrared systems might identify specific materials but lack comprehensive tracking capabilities for overall waste streams. The Greyparrot Sync API integration suite enhances interoperability by connecting real-time data from the Analyzer with existing hardware and software across different brands.

Data-Driven Insights Lead to Sustainable Packaging

Greyparrot’s innovative approach extends beyond operational improvements. In 2023 alone, these systems assessed over 25 billion waste objects worldwide, generating comprehensive datasets that help packaging manufacturers design more sustainable alternatives easier to recover. These detailed insights provide valuable information about packaging performance throughout its lifecycle.

Pritchard notes that machine vision has been used in the waste sector for decades, but “digitization and automation through this technology will become increasingly vital as facilities face growing needs for processing efficiency.”

Last Updated: 2025-09-04 23:54:42