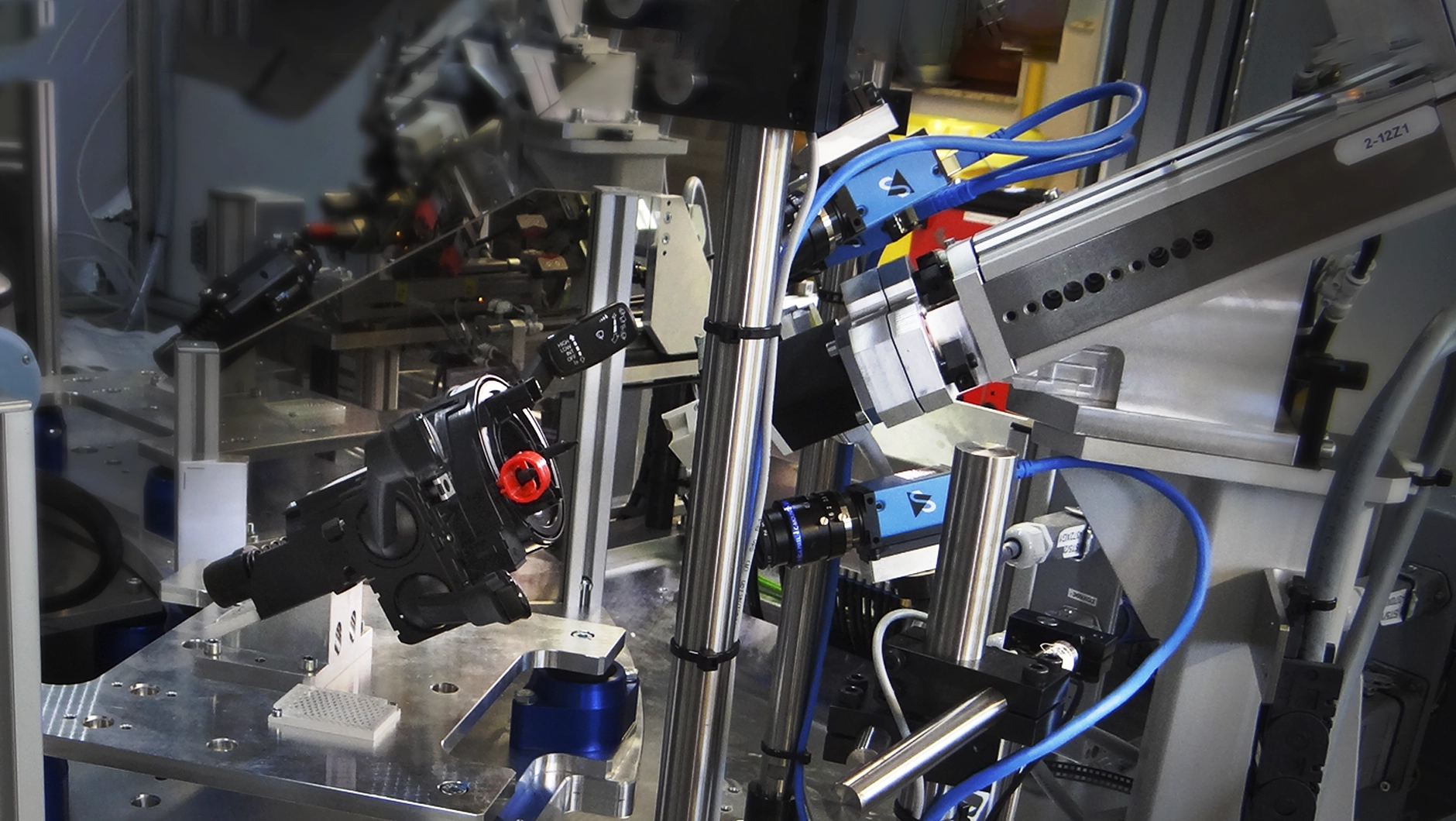

Multi-Camera Vision Inspection System with Cobots for Steering Column Quality Control

The automotive industry’s pursuit of zero defects relies heavily on advanced test equipment like that from ITgroup, which integrates industrial cameras for precise inspection tasks such as defect detection and dimensional accuracy checks. These systems utilize high-resolution GigE Vision cameras to capture detailed images, enabling automated analysis with low error rates.

GigE Vision cameras provide reliable, high-speed data transfer over Ethernet, making them ideal for complex applications like multi-camera setups in automotive testing benches. Their compact design supports long cable runs up to 100 meters and offers features like HDR imaging to enhance visibility of defects on colored surfaces.

ITgroup’s systems often combine both 2D and 3D imaging approaches. Standard door panel inspections use multiple high-resolution cameras for tasks such as surface defect detection, while advanced setups like LumIT XL employ light field technology with numerous cameras to create detailed 3D point clouds without the need for IR or lasers.

As Industry 4.0 demands more flexibility and customization, modular test systems are crucial. ITgroup focuses on remote maintainability and expandability through software integration, allowing efficient adjustments via network interfaces rather than physical modifications.

The future of automated inspection involves integrating AI is promising with increasing use of deep learning algorithms to improve accuracy further, as manufacturers increasingly adopt AI-driven solutions for handling smaller batch sizes and reduced cycle times. This ensures that quality control remains robust while adapting to evolving production needs.

Multi-Camera Systems in Automotive Quality Control

Last Updated: 2025-09-05 00:11:16