Inline Quality Control with Zero Errors: The IQZeProd System

Visual inspection remains a fundamental component of most quality control workflows. However, when performed manually, it presents significant challenges including high costs, frequent errors, inefficiency, and common issues such as 10-20% product rejection rates (pseudo-scrap) alongside production bottlenecks.

[…]

The IQZeProd Solution

Researchers at Chemnitz University of Applied Sciences have developed the innovative IQZeProd system—a groundbreaking solution designed for automated inline quality assurance. Funded by Germany’s Federal Ministry for Economic Affairs, this collaborative project brings together industry partners like The Imaging Source Europe GmbH and Fraunhofer Institute for Machine Tools and Manufacturing Systems Engineering—supported by the German Research Association for Measurement, Control and Systems Technology (DFMRS). The system delivers an inline-capable solution with 100% control compliance.

Overview of the IQZeProd System

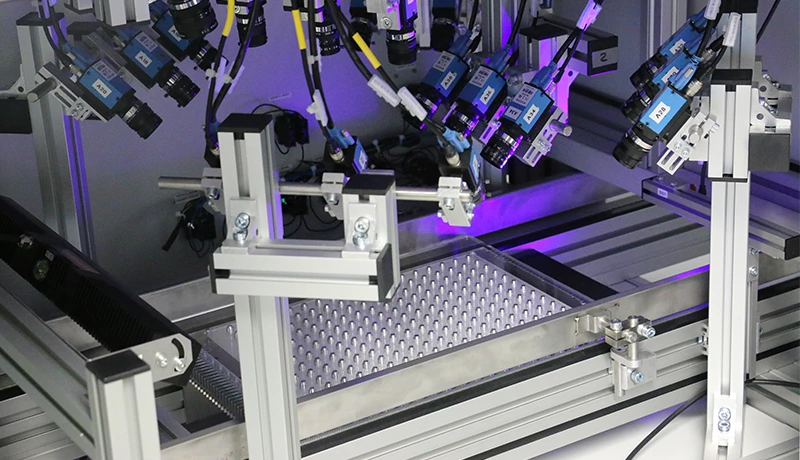

The project’s industrial-grade hardware platform integrates over 20 different sensors to deliver a data stream exceeding 400 MB/s at speeds up to 1 m/s. This advanced infrastructure enables rapid processing through massively parallel computation, ensuring real-time evaluation capabilities essential for inline quality assessment.

Key System Components and Technology:

Modular Framework Architecture

The system’s modular framework approach leverages plug-in components that can be extended using various imaging libraries. Its design incorporates three primary hardware categories:

- Massively Parallel Processing: 28 CPU cores plus GPU acceleration enabling parallel task execution across blue and yellow modules (see Figure)

- Deep Learning Integration: Capable of applying neural network-based defect detection for complex surfaces like wood or textiles

- Customizable Plug-in Architecture: Flexible quality control programs developed rapidly using standard imaging libraries

Field-of-View Flexibility: Zoom Functionality for Diverse Components

The system can handle various component types and sizes through adjustable field of view (FOV) capabilities. Imaging Source’s monochrome zoom cameras with integrated motorized zoom lenses provide rapid adjustments, essential when testing diverse materials including metal parts, wood, textiles, and 3D-printed plastics.

Deep Learning Integration for Complex Materials

The system supports both classical image processing algorithms and deep learning methods depending on application requirements. Machine learning is typically reserved for challenging cases like organic materials with irregular textures where traditional approaches reach their limits. In such instances, neural networks offer powerful defect detection capabilities while maintaining control over algorithm adjustments during commissioning.

Performance Characteristics:

- Processing Speed: Capable of handling throughput speeds up to 1 m/s

- Cycle Time: Maintains a demanding 10-second cycle time for processing approximately 400 images (from the 20-camera array) plus additional sensor data within tight production cycles

Technical Highlights

High-Performance Camera Selection Criteria:

Researchers prioritize several key camera specifications:

- Bit rate optimization via firmware-based region of interest (ROI) cropping

- Reliable image transmission at high speeds with fragment-free delivery essential for inline processing

- Adjustable field-of-view functionality provided by motorized zoom cameras, especially valuable in demo/test systems where components vary significantly in size and shape

High-Frequency Data Stream Processing:

The system processes data streams approaching 400 MB/s from over 20 sensors including hyperspectral imaging and roughness measurement. This necessitates parallel computing resources with the hardware leveraging both CPU cores (CPU) and graphics processing unit (GPU). The modular framework supports integration of diverse sensor types beyond standard machine vision tasks, incorporating non-visible spectrum technologies like terahertz or radar for comprehensive defect detection.

Deep Learning Integration

Because Xeidana’s support for massively parallel processing enables deep learning applications in cases where traditional methods reach their limits. Machine learning is typically reserved for organic materials with irregular textures such as wood and leather due to challenges associated with algorithm adjustments during commissioning.

Last Updated: 2025-09-05 00:20:02