Sony introduces Polarsens global-shutter CMOS image sensors featuring multi-directional polarization for enhanced material visualization and glare reduction.

Sony’s Polarsens™ 5.1 MP global-shutter CMOS image sensors (IMX250MZR/ IMX250MYR) capture visual data that other standard monochrome and color sensors cannot obtain. The Imaging Source has introduced new USB 3.0 and GigE polarization cameras featuring Polarsens technology, which employs four-directional (0°, 45°, 90°, 135°) nanowire micro-polarizers placed in front of each 2x2 pixel array to deliver multi-directional polarized images.

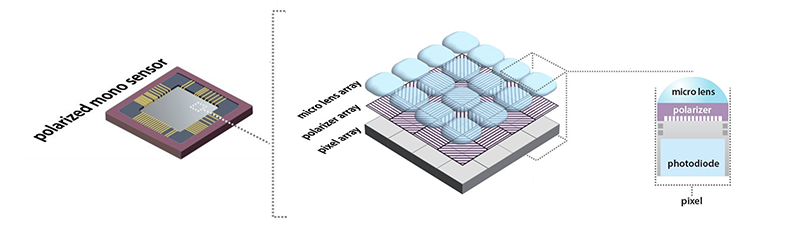

An illustration depicts the structure of Sony’s Polarsens sensor. Many materials, such as plastics, glass, metals, and liquids, exhibit intrinsic polarization properties that can cause glare or image artifacts in standard intensity images. Standard intensity images of transparent objects often provide limited visual data.

The sensors’ polarization filters utilize these properties to visualize material stress and surface scratches while reducing glare, improving edge detection, or enhancing contrast in low-contrast materials.

Images from the DZK 33UX250 camera show how processing polarization data can reveal details. For example, using AoLP with HSV color mapping highlights residual stress in plastic, while DoLP enhances contrast for defect inspection by reducing glare.

A standard intensity image of a black granite pyramid appears low-contrast (left). Applying DoLP adds clarity, and using AoLP with HSV mapping provides additional information useful for segmentation.

The cameras support on-chip four-channel polarization processing, allowing users to isolate specific channels for further analysis. Available in both color and monochrome variants, the 5.1 MP sensors offer either GigE (max. 24 fps) or USB 3.0 interfaces (max. 75 fps). For more details, refer to our whitepaper.

Last Updated: 2025-09-05 00:24:29