Inkjet Technology Workshop: Utilizing the DMK 33GP031 for Dropwatching

Since its commercial viability in the 1970s, inkjet printing has consistently captured researchers’ attention. At its core, it is a no-contact method that enables precise and high-frequency digital delivery and positioning of extremely small volumes of material or fluid. Fundamentally, inkjet technology aligns with additive manufacturing principles, finding applications today in printed electronics, direct printing, ceramics and textiles. Experimental uses include jetable fluids and substrates such as live-cell printing for biofabrication, organic semi-conductors and organic light-emitting diodes (OLEDs).

The Institute for Printing (iPrint) at the University of Applied Sciences of Western Switzerland began offering an inkjet training course in 2015. This multidisciplinary program provides one week of theoretical and practical training focused on various components of inkjet systems, enabling professionals to enhance their expertise across different aspects of this technology.

The DMK 33GP031: A Key Component for Dropwatching

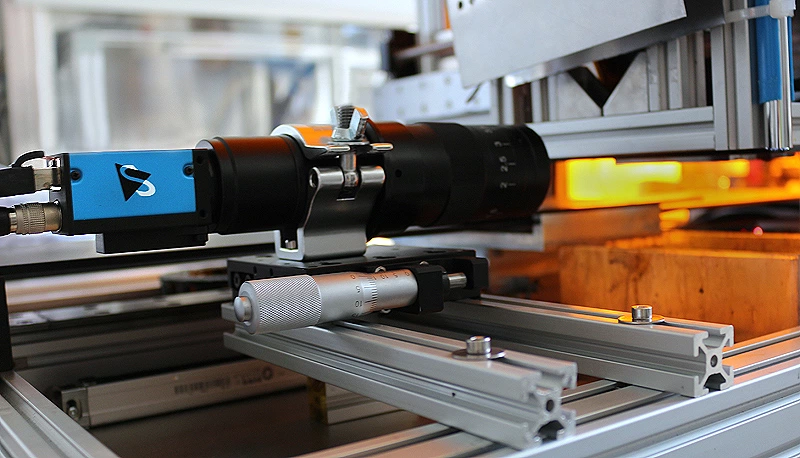

During the course, participants learn a critical aspect involves determining print quality delivered by an inkjet print head. This process begins with analyzing droplet properties—drop velocity, jetting direction, satellite drops and drop volume—which must be tightly controlled to meet application requirements. Machine vision systems support this analysis through imaging techniques known as dropwatching.

The Imaging Source’s DMK 33GP031 GigE monochrome camera was selected for its effectiveness in capturing droplet images during printing. This technology enables continuous measurement of critical parameters, supporting performance optimization and print system reliability verification. Possible dropwatching configurations include nozzle plate analysis, multi-camera monitoring, overlaid imaging or wavelength-specific approaches—each tailored to specific requirements while maintaining high-precision standards.

Multidisciplinary Nature of Inkjet Research

As noted by iPrint, inkjet research inherently requires cutting-edge skills from mechanical engineering, chemistry and nanotechnologies due to its multidisciplinary nature. Participants in their course are typically engineers or chemists with expertise in one area but a limited understanding of other aspects—looking to expand their knowledge base through cross-system awareness training programs designed for practical application development worldwide.

Last Updated: 2025-09-05 00:49:49